Imagine you’re building a house, or maybe just fixing a leaky faucet. You head to the hardware store and see all sorts of pipes, including ones labeled “PEX.” What is PEX, and why are there different types?

PEX stands for cross-linked polyethylene. It’s a popular type of plastic piping used for water supply lines in homes and businesses. But not all PEX is created equal. Two common types you’ll encounter are PEX A and PEX B.

Knowing the difference between these two can help you make the right choice for your plumbing project, whether you’re a DIY enthusiast or a seasoned professional. This article will break down the differences between PEX A and PEX B, explaining their unique characteristics and helping you understand which one might be best for your needs.

What is PEX Piping?

Before we dive into the specifics of PEX A and PEX B, let’s understand what PEX piping is all about. PEX is a flexible plastic pipe that has become a popular alternative to traditional copper or rigid plastic pipes.

Advantages of PEX Piping

- Flexibility: PEX pipes can bend around corners, making installation easier and reducing the need for fittings.

- Resistance to Corrosion: Unlike metal pipes, PEX is not susceptible to corrosion or mineral buildup.

- Freeze Resistance: PEX pipes are less likely to burst in freezing temperatures due to their flexibility.

- Quiet Operation: PEX piping systems are quieter than metal pipes, reducing water hammer noise.

PEX A and PEX B: Manufacturing Process

The main difference between PEX A and PEX B lies in how they are manufactured. This affects their properties and how they are installed.

PEX A Manufacturing

PEX A is manufactured using the peroxide (or Engel) method. This process creates cross-linking throughout the entire pipe wall, resulting in a more flexible and robust material. Think of it like a web of interconnected molecules that make the pipe strong and stretchy.

PEX B Manufacturing

PEX B is manufactured using the silane (or moisture-cure) method. This process creates cross-linking primarily on the surface of the pipe wall. This results in a slightly less flexible pipe compared to PEX A.

PEX A and PEX B: Major Differences

| Feature | PEX A | PEX B |

|---|---|---|

| Manufacturing Method | Peroxide (Engel) method | Silane (moisture-cure) method |

| Flexibility | More flexible | Less flexible |

| Cost | Generally more expensive | Generally less expensive |

| Installation | Typically uses expansion fittings | Typically uses crimp or clamp connections |

| Kink Resistance | Higher | Lower |

| Chlorine Resistance | Higher | Lower |

Installation Methods

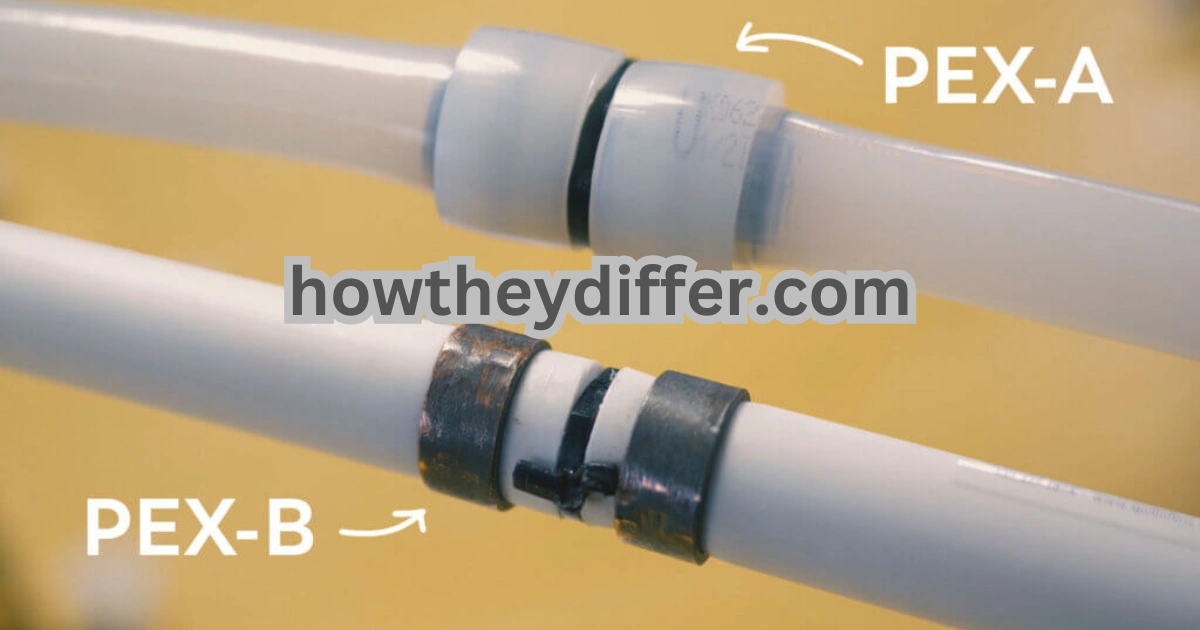

The installation methods for PEX A and PEX B also differ due to their varying flexibility and molecular structure.

PEX A Installation

PEX A is typically installed using expansion fittings. This involves using a special tool to expand the pipe, allowing the fitting to be inserted. Once the pipe shrinks back to its original size, it creates a secure, watertight seal.

PEX B Installation

PEX B is commonly installed using crimp connections or clamp connections. Crimp connections involve using a special tool to compress a metal ring around the pipe and fitting. Clamp connections use a similar concept but with a different type of clamp.

Pros and Cons of PEX A and PEX B

A comprehensive account on advantages and disadvantages of PEX A and PEX B are given as:

PEX A

Pros:

- Superior flexibility

- Higher kink resistance

- Easier to repair

- Higher chlorine resistance

Cons:

- More expensive

- Requires specialized expansion tool

PEX B

Pros:

- Less expensive

- Wider availability of fittings

- Easier to find installation tools

Cons:

- Less flexible

- More susceptible to kinks

- Lower chlorine resistance

Applications of PEX A and PEX B

Both PEX A and PEX B are suitable for a variety of plumbing applications, including:

- Potable water supply lines: Delivering clean water throughout your home.

- Radiant heating systems: Providing efficient and comfortable floor heating.

- Hydronic baseboard heating: Distributing hot water to baseboard heaters.

Conclusion

While both PEX A and PEX B are reliable options for plumbing systems, they have distinct characteristics that make them suitable for different applications.

PEX A offers superior flexibility and kink resistance, while PEX B is a more budget-friendly option. Understanding these differences will help you choose the right type of PEX piping for your next plumbing project.

FAQs

Some of the frequently inquired questions regarding the differences between PEX A and PEX B are as follow:

Is PEX A or PEX B better for my home?

The best choice depends on your specific needs and budget. If flexibility and kink resistance are important, PEX A might be preferable. If cost is a major concern, PEX B could be a suitable option.

Can I connect PEX A and PEX B pipes together?

Yes, you can connect PEX A and PEX B pipes using special transition fittings.

What is the lifespan of PEX piping?

PEX piping has an expected lifespan of 40-50 years or more with proper installation and maintenance.

Is PEX piping safe for drinking water?

Yes, PEX piping is approved for potable water applications and does not leach harmful chemicals into the water.

Do I need a special tool to install PEX piping?

Yes, you will need specific tools for either expansion fittings (PEX A) or crimp/clamp connections (PEX B).